|

|

Allstars Inspection 宏厦驗屋 |

Common Electrical Panel Problems | |

|

Corrosion |

|

Open Knockouts/No clamps

A panel enclosure is designed with multiple wire or breaker “knock-outs” that allow the installer to make an access point for wires and breakers. Many times, however, these knock-outs are removed and nothing is put in their place, leaving gaps into the electric panel enclosure. These gaps, especially at the front cover where the breakers reside, can be dangerous as they allow access into the enclosure. Wires running through these openings do not have the proper clamps in place to keep the wires from moving around and getting damaged. Adding covers and strain relief clamps can be a relatively simple fix to these problems. |

|

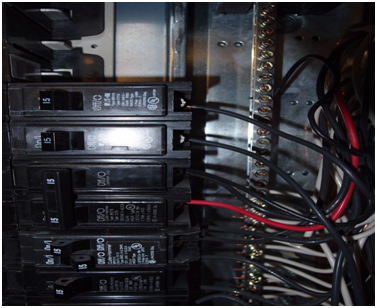

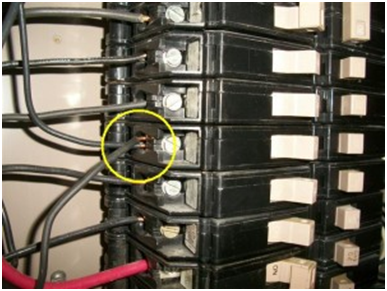

Double Taps

Multiple hot or neutral wires are physically connected to a single lug (on a breaker or a bar) where only one wire should be connected.

Exception for bell or telephone system low voltage transformer |

|

Oversized breakers/fuse

“Overfusing” |

|

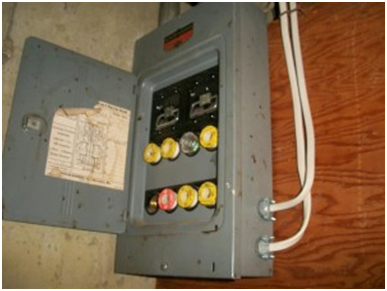

Old fuse panel or small service

Just don’t have enough room to handle the electrical needs for today’s homeowner. Mostly 60amps service |

|

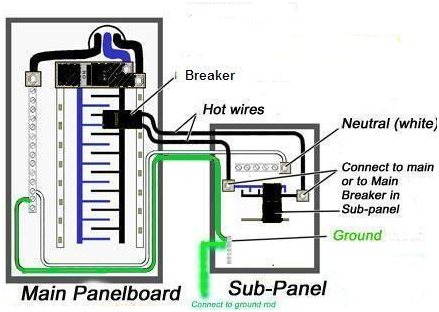

Neutral should be attached to a terminal, but not by-pass service box before subpanel |

| Fuse should not be upstream of disconnect switch | |

| Ground wires should be bonded to service box and subpanel | |

| Neutral should not be fused in old wiring system | |

| Subpanel should be fused at main panel, not upstream of main panel | |

|

Three wire conductor, breaker for red wire and breaker for black wire must be tied i.e. split receptacle |

Common Wiring and Outlet Problems | |

|

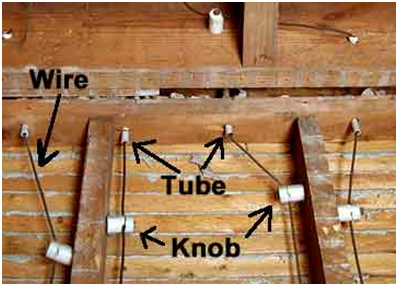

Knob & tube wiring (Pre1920) Knob and tube wiring is usually found in homes built about 50 years ago that have not had the wiring updated. Usually it is found at older 60 amp services. It consists of only a hot (black) and neutral (white) wire with no ground wire. Both wires must run separately to fixtures as opposed to those used now which are contained within one plastic sheathing. In recent years some home insurance companies have begun to refuse to insure homes with knob and tube wiring. |

|

Aluminum wiring (Mid 1960~1978)

Studies confirm that these homes are more likely to have a fire hazard condition present than homes wired with copper. Most of these homes were built in the 1960’s to late 1970’s.

Problems began to surface where aluminum was used in branch circuit wiring. These are the smaller wires that bring electricity from the electrical panel to the plugs, switches and lighting fixtures. Testing revealed that aluminum wiring has some problematic characteristics that are not found with copper. Aluminum tends to oxidize when exposed to air, resulting in overheating, and eventually failure at the termination points. Aluminum is not as resilient as copper and also has a higher rate of expansion, which can cause loose terminations and connections, resulting in possible arcing, melting and even fire. Breakage, due to improper stripping of the wires or over-tightening of the splices during the installation stage, has created further problems. |

|

Double Taps

Multiple hot or neutral wires are physically connected to a single lug (on a breaker or a bar) where only one wire should be connected. |

|

Oversized breakers/fuse

“Overfusing” |

|

Old fuse panel or small service

Just don’t have enough room to handle the electrical needs for today’s homeowner. Mostly 60amps service |

|

Overhead wire < 20ft above road, across roof or < 3ft clearance from window |

|

Gas piping should be grounded |

|

There should be Jumper ground wire for water meter |

|

Wires too close to duct/pipe |

| Indoor cable used at outdoor (only NMD conductor is allow) | |

|

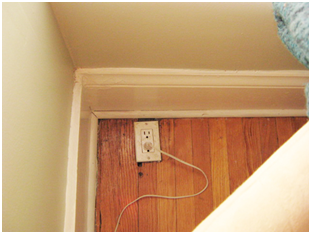

Electrical outlet should not be

1)above electric baseboard heaters, 2)on counter top OR 3)on ground |