|

|

Allstars Inspection |

Common Gas Piping Problems | |

|

Poor gas meter location |

|

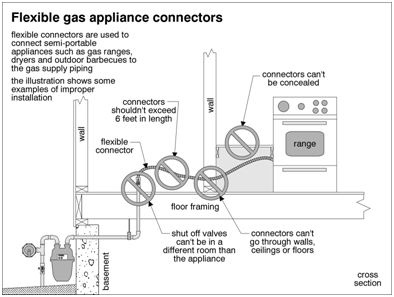

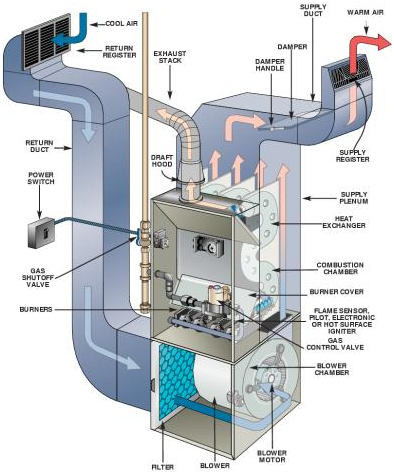

Flexible gas appliance connectors

Flexible connectors are used connect semi-portable appliances such as gas ranges, dryers and outdoor barbecues to the gas supply piping Flexible connectors can’t go through walls, floors or ceiling, nor can they be concealed. 6 feet is the limit. |

Common Gas Furnace Problems | |

|

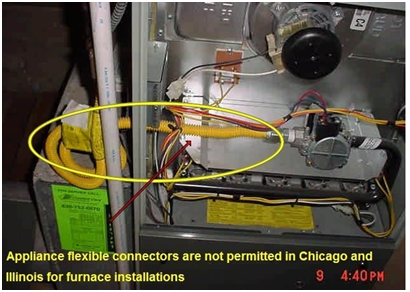

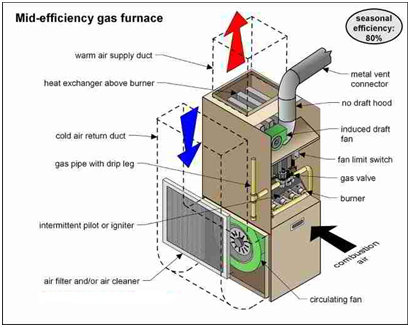

Gas Furnace Diagram |

|

Scorching

(note that the photo shown is a hot water tank, not gas furnace, this photo is used to illustrate scorching)

Visible at the heat rollout shield, as the gas valve, at the wiring, on the faceplate of the heat exchanger. This is a fire hazard caused by: -overfiring of the burner -lack of combustion air supply -a chimney obstruction or downdraft -underfiring of the burner |

|

Flame wavering

If the flame is distorted when the house fan comes on, this is indication of a crack in the heat exchanger. This is a life safety hazard since carbon monoxide could enter the house. |

|

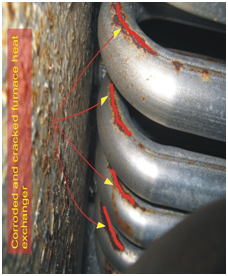

Cracks in heat exchanger

Furnace short cycling, on and off frequently may indicate cracks in heat exchanger. This is a life safety hazard since carbon monoxide could enter the house. |

|

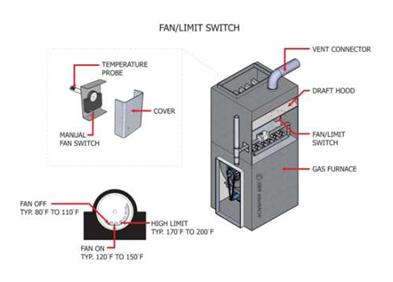

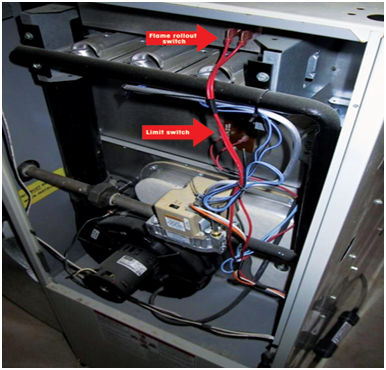

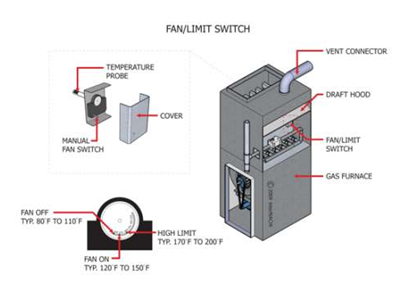

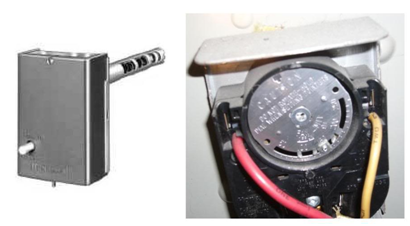

Fan/limit switch

Switch maybe set wrong, scorching, rusting or improperly wired |

|

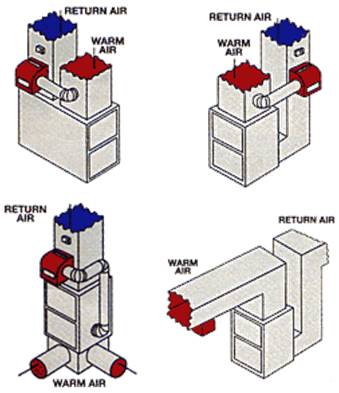

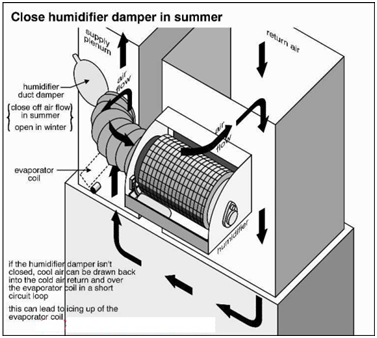

Humidifier location

Drum-type humidifier should be located on the return plenum, not the supply plenum. If leaks develop and the humidifier is on the supply plenum, the water will leak onto the heat exchanger and cause rust of the heat exchanger and eventually develop cracks. |

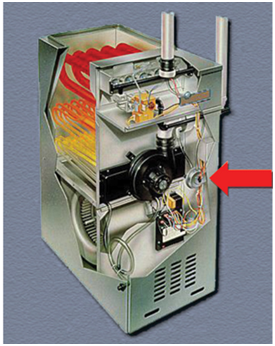

Common Mid-High Efficiency Furnace Problems | |

|

Components of the induced-draft condensing furnace

-differential pressure switch to make sure the induced-draft fan is running -heat switch or spillage switch to shut the furnace off if heat or flame rolls out -blower cover interlock prevents the furnace and induced draft fan from running if the lower compartment cover is missing |

|

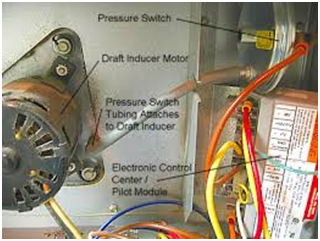

Differential pressure switch

Make sure the induced draft fan is running and that the vent isn’t blocked |

|

Spillage switch

Shut off the furnace on high temperature at the front of the burner if there is a flame rollout or spillage condition If the furnace shuts off because of this high temperature sensor, you should be able to fell heat spilling back out through the front of the burner opening before it shuts off if this not a direct vent furnace |

|

Neutralizer

Check neutralizer is not clogged and condensate is discharging to an appropriate location |

|

Automatic vent damper

Damper closes as soon as burners turn off to keep residual heat in the building Damper opens just before burners come on If the unit is not functioning properly, the fail-safe damper position is open |

Common Vent Problems | |

|

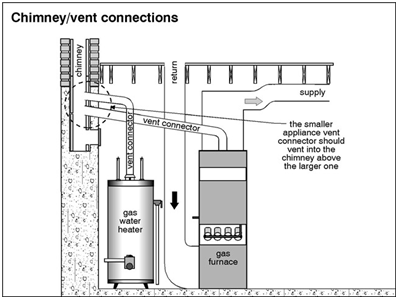

Poor manifolding

For multi vent connector, smaller appliance should be connected above the larger appliance. Otherwise there will be exhaust spillage. |

|

Improper vent connector

Vent connector should not go through walls/ceiling. Vent connector should be connected to chimney or metal chimney. |

|

Size of vent connector

The vent connector diameter should match the size of the flue collar. If the vent connector is too large or too small, condensation or spillage could result. |

|

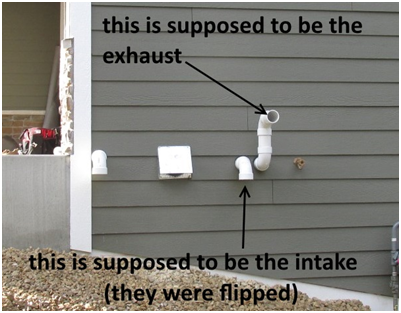

Improper sidewall vent locations

• 3’ window clearance • > 4’ below soffit • 3’to6’ from gas regulator • 3’to6’ from combustion air inlet for other appliance • should not discharge below confined porches or decks • >1’ above grade • > 7’ above walkway |

Common Combination Furnace/Water Heater Problems | |

|

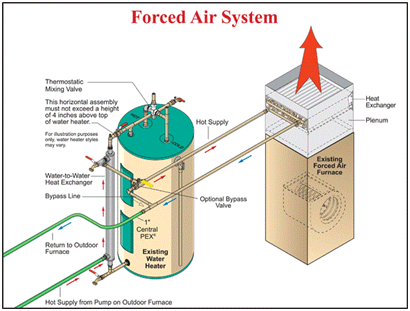

Combination furnace/water heater system

Pump hot water from the water heater to the coil in the furnace. Pro: less expensive because of shared burner, less piping, no heat exchanger. Con: hot water have to be able for domestic use and to heat house. Larger water tank – at least 60gallons. |

|

Tempering valve

To improve the efficiency of the fan coil unit, the water heater temperature is sometimes turned way up. A tempering valve adds a little cold water in with the hot so that it is suitable for domestic use. Check adjustment of tempering valve if water is too hot or house faucets is not hot enough |

Common Oil Furnace Problems | |

|

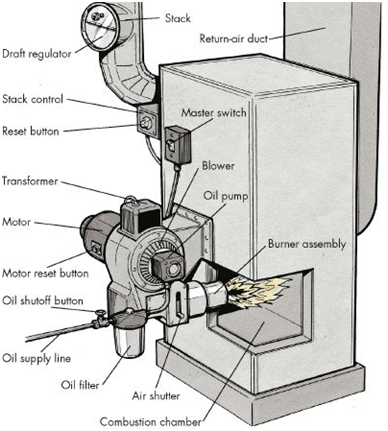

Oil Furnace

Furnace use oil as the fuel to heat house. There is oil tank inside or outside of the house. |

|

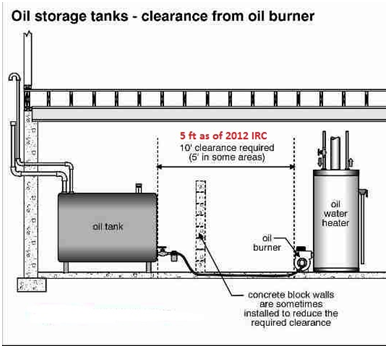

Oil Storage tanks

Oil tank must be more than 10ft from burner unless separated by masonry wall Oil line should be 2” for outdoor before switching to smaller tubing indoor |

|

Oil leaks

Check oil leaks at oil line connections, oil gauge, bottom of tank, shut off valve and oil filter Leakage of oil from a buried tank is an environmental concern and remediation of contaminated soil is a greater expense. The life of a buried tank is 10 to 20 years |

|

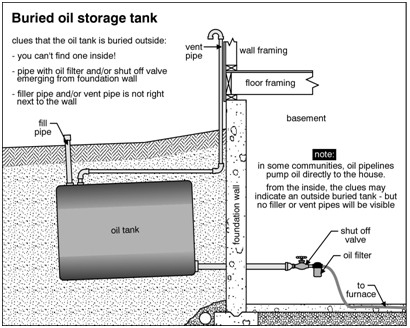

Fill cap and gooseneck

Buried oil tank can be identified by vent line gooseneck and fill line cap. Check if there is cap for fill line |

|

Oil Burner

There is at least 24” clearance between burner and any combustibles |

|

Combustion chamber

Picture shows a heating furnace with soot blow-back around the oil burner probably means there is backpressure in the combustion chamber - an improper operating condition that may be unsafe. |

|

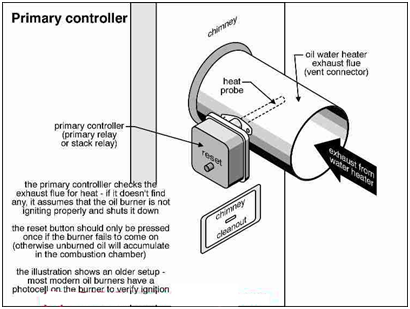

Primary Controller

Checks the exhaust flue for heat |

Common Hot Water Boiler Problems | |

|

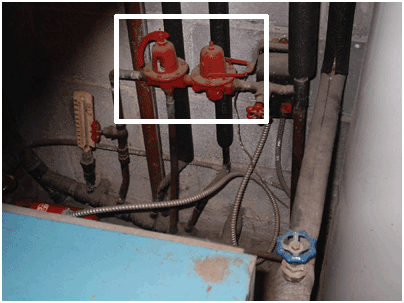

Hot water boiler

Use piping to carry hot water to the radiator for heating the house Water boiler is at the left of the picture, water heater is at the right. |

|

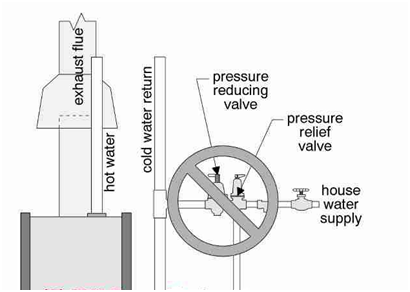

Pressure Relief Valve

Pressure relief valve open to allow excess pressure and water to escape. It can also be opened manually by flipping up the leveron the top Look for leak on this valve |

|

High Temperature limit switch

This switch is the same function as the high-temperature limit on a furnace, it shuts off the boiler if the temperature gets too high. |

|

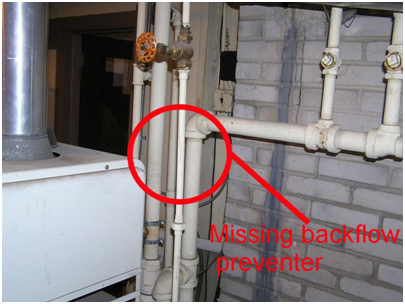

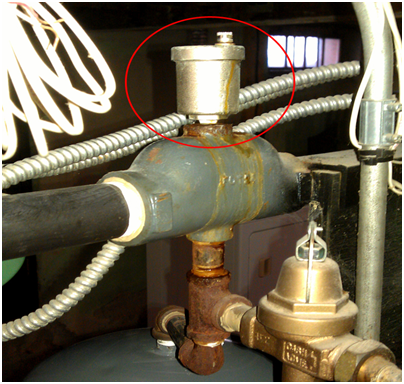

Backflow preventer

Backflow preventer prevents contaminated waterinto the domestic water pipe |

|

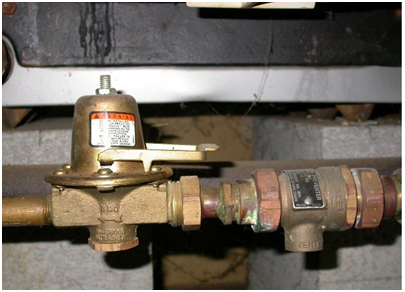

Pressure Reducing Valve

Pressure in the hot water boiler is reduced if boiler pressure is greater than valve setting Pressure reducing valve should be upstream of the pressure relief valve |

|

Air Vent or Air Eliminator

Get rid of air in the water, air vents are more important on boilers with pumps since pump can be damaged by air pockets. Check for leaking |

|

Low-temperature limit, aquastat or primary control

Keep the water in the boiler hot so that it can respond quickly to a call for heat. It is typically strapped to the hot water piping above the boiler Usually set at 140°F to keep water in boiler hot |

|

Radiator bleed valve

Air bleed valve should be located near the top of every radiator to let trapped air out, so the water can circulate properly. Check for leaking. |

Common Fire Place and ChimneyProblems | |

|

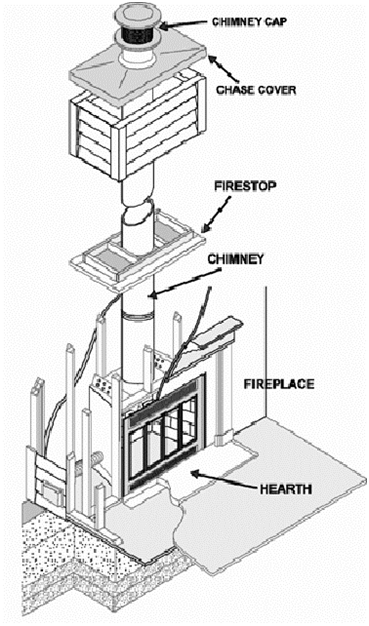

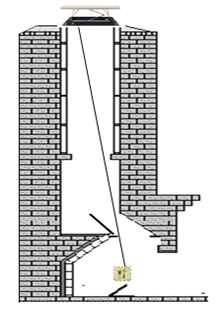

Fire place / Chimney |

|

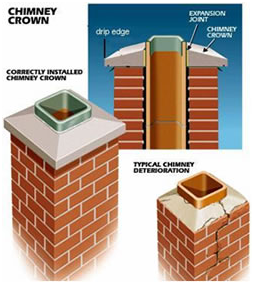

Chimney Cap/Crown

Protect the top of the chimney from weather |

|

Chimney movement

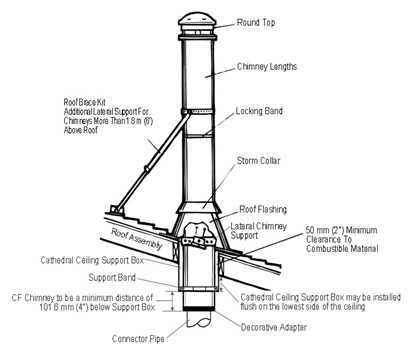

Maybe cause by differential movement. It is a structural and fire hazard. Exhaust gas may enter house. Metal vent greater than 5ft and masonry greater than 12ft above roof require lateral support |

|

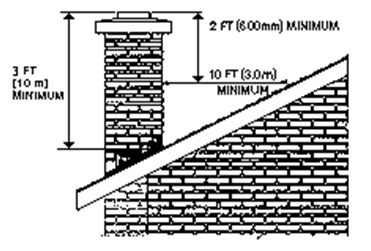

Chimney Clearance

Chimney should be at least 3ft above the roof and at least 2ft higher than anything within 10ft of the chimney, horizontally |

|

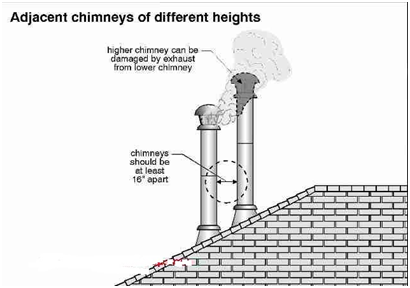

Adjacent chimneys

Adjacent should be at least 16” apart. |

|

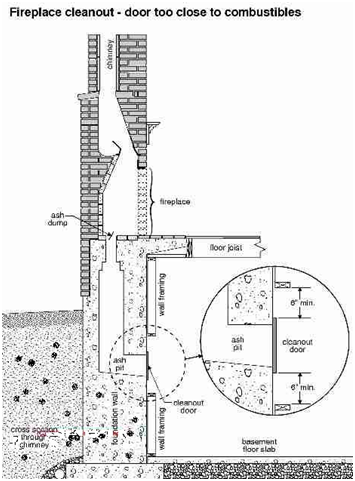

Fire Place Cleanout

Fireplace cleanout should not be too close to combustibles. Fire stop is required over the top of the cleanout. |

|

Creosote Deposits

Deposits thicker than 1/8” should be cleaned. Black, shiny creosote is a bigger concern than flaky, dark brown creosote. Too much creosote is a fire hazard. |

|

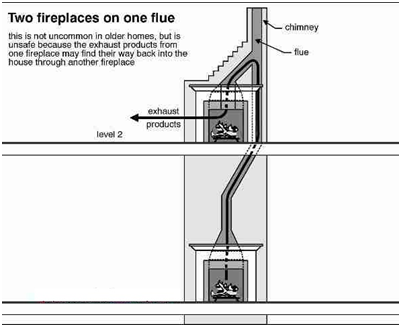

Dedicated flue for fireplaces

dedicated flue. These are unsafe because the exhaust products from one fireplace can find their way back into the house through another fireplace. |

|

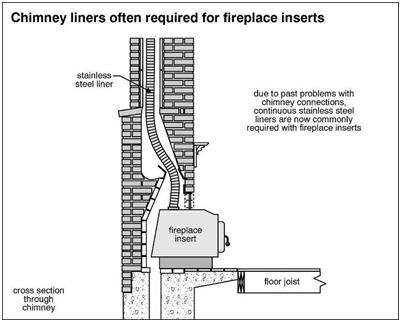

Fireplace inserts

Fireplace inserts weights more than 200lbs and require some tool to remove |

|

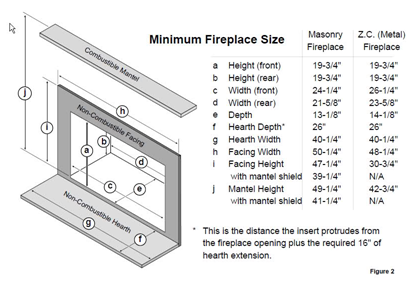

Fireplace size, hearth extension dimension and raised hearths |

|

Gas igniter

Gas igniters and burner pipe should not be buried in embers/ashes |

|

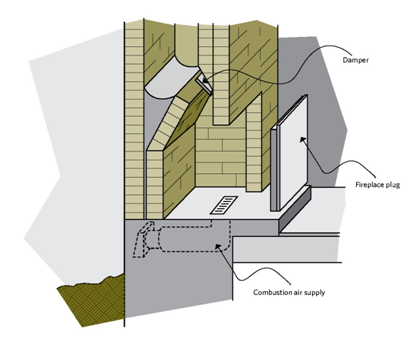

Outdoor combustible air

This is common for house built in 1970’s. There is usually an operating damper with a hinged air inlet hood that can be closed. |

|

Fireplace dampers

Dampers are either located at the top of the chimney or operated with a handle at the top of the firebox. The fall-safe (broken cable) position for chimney-top dampers should be open. |

Common Wood Furnace Problems | |

|

Wood Furnace

Use wood pellets as the fuel to provide heating to the house. Wood furnace does not have automatic fuel supply, burner, automatic ignition system. Ash removal required. Need to watch for -creosote buildup, -inoperative combustion damper, -inoperative forced draft combustion fan, -high temperature clearance from combustible framing members |

|

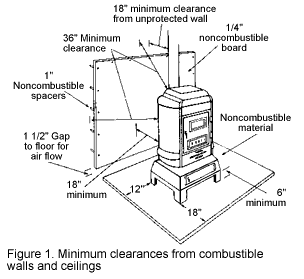

Wood stove floor protection and clearance

Floor protection must be non-combustible hearth pad. |

Common Electric Baseboard Problems | |

|

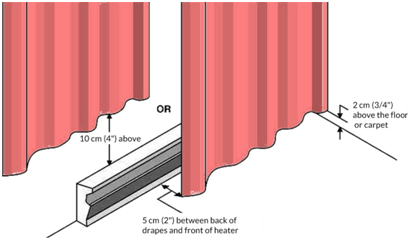

Electric baseboard

It is a fire-hazard if furniture or drapes are too close to the heater |

|

Bent fins

Bent or dirty fins result in uncomfortable room temperature or excessive heating costs. |

Common Electric Furnace Problems | |

|

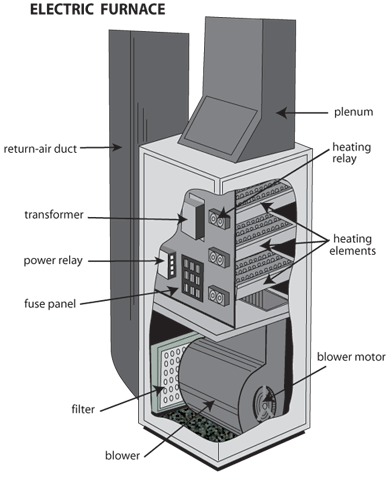

Electric Furnace

For a 25kW electric furnace, there should be 5 heating elements (typically 5kW each) The electric element comes on in sequence. The total time from 1st element to the last element should be from 30sec to 360sec. |

|

Fan Limit Switch

Fan limit switch should have a setting at 200°F |

Common Wall and Floor Furnace Problems | |

|

Floor Furnace

The grate should be designed to walk on. Floor furnace may not be allowed for some jurisdiction. |

|

Wall Furnace

Wall furnaces use BW vent, gas, undersized and has poor access. They are not allowed in bedrooms or bathrooms. |